Goffs Quarry

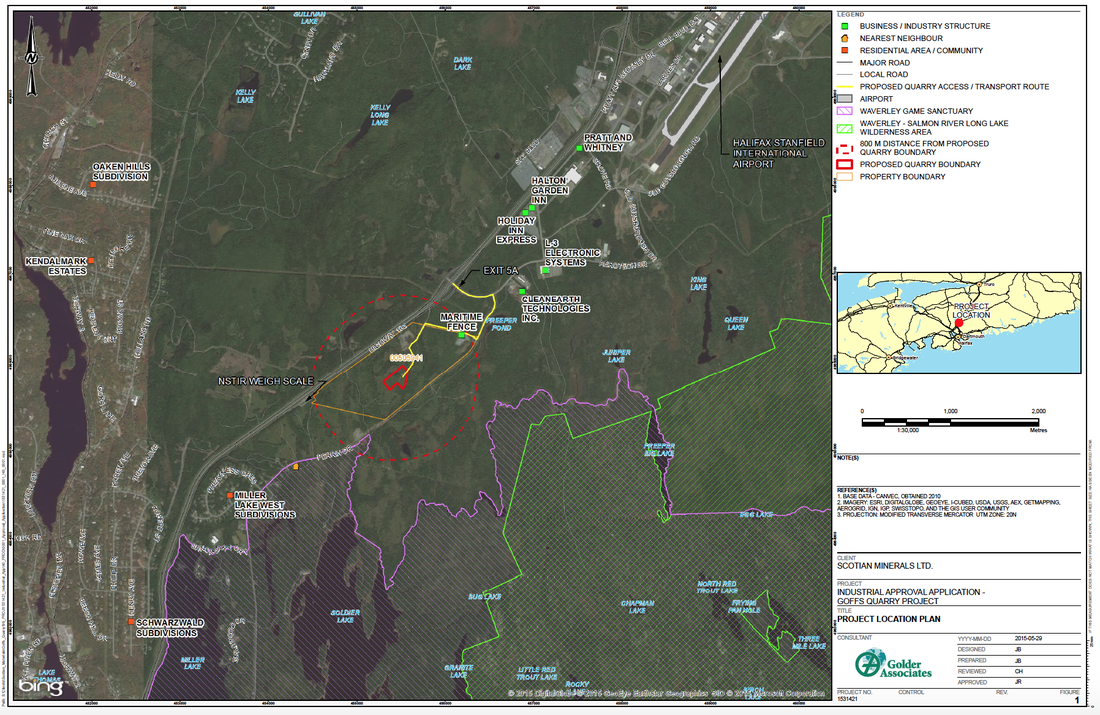

The Project, as proposed by Scotian Materials Ltd. (Scotian) consists of the construction, operation, decommissioning and reclamation of a 3.99 ha construction aggregate quarry in Goffs, Nova Scotia. The Project is located within Halifax Regional Municipality (HRM) approximately four (4) kilometres (km) south and west of the Halifax Stanfield International Airport and immediately adjacent to the Aerotech Industrial Park located northeast of the Project.

Geographic Location

The proposed Project is on lands owned by Scotian Materials Limited located in Goffs, Halifax County, Nova Scotia (PID 00505941). The Project property is bounded to the north by lands of Nova Scotia Natural Resources (PID 40885279); to the west by Highway 102; to the east by lands of Scotian Materials (PIDs 41356866, 41356874 & 00505925) and private lands (PID 00515528); and to the south by private lands (PID 41197401) also owned by Scotian Materials.

The proposed Project is on lands owned by Scotian Materials Limited located in Goffs, Halifax County, Nova Scotia (PID 00505941). The Project property is bounded to the north by lands of Nova Scotia Natural Resources (PID 40885279); to the west by Highway 102; to the east by lands of Scotian Materials (PIDs 41356866, 41356874 & 00505925) and private lands (PID 00515528); and to the south by private lands (PID 41197401) also owned by Scotian Materials.

The general location of the Project was identified in consideration of its proximity to the existing access road and the former quarry operated by Nova Scotia Transportation and Infrastructure Renewal. The proposed footprint of the quarry within the land parcel was determined based on site topography, the depth of overburden and proximity / setback from existing features (e.g., watercourses, wetlands).

The adjacent and surrounding lands, also owned by Scotian, include an existing clay pit and a former rock quarry which was operated periodically over the past few decades to support provincial transportation and infrastructure projects. Other land uses in the vicinity of the Project include a variety of business and industrial operations north and east of the site in the Aerotech Industrial Park such as Maritime Fence, Irving Oil CNG, Clean Earth Technologies Inc., and L3 Electronics Systems as well as the Halifax Stanfield International Airport. Located west of the proposed quarry is the north bound Highway 102 weigh station, operated by the Department of Transportation and Infrastructure Renewal (NSTIR). Further west, across Highway 102, are a number of residential subdivisions in Fall River. Approximately 1.5 km south west of the Project is a residential community known as the Miller Lake West subdivision.

Immediately south of the site is Perrin Drive which runs northeast – southwest. The majority of Perrin Drive, between the entrance to the quarry and Miller Lake West subdivision, is impassable via automobile. The Maritimes and Northeast Pipeline Halifax Lateral runs parallel to Perrin Drive, on the south side. Scotian owns the land parcels on both sides of Perrin Drive which are also undeveloped. The Waverley Game Sanctuary and the Waverley Salmon River Long Lake Wilderness Area are located south and east of the Project.

Scotian commissioned a number of field surveys across the properties purchased in the vicinity of the proposed Project to support plans for various types of potential developments (e.g., commercial, residential, industrial). Surveys were conducted for wetlands and vegetation communities, surface water and fish / fish habitat, and wildlife. The boundary of the proposed Project footprint was selected to avoid wetlands and watercourses and optimize the resource available and access to it. As specified in the Pit and Quarry Guidelines (NSEL 1999), a 30 metre buffer will be maintained between the quarry footprint and all watercourses and wetlands. The quarry will make use of existing, well-established access roads within the property.

The adjacent and surrounding lands, also owned by Scotian, include an existing clay pit and a former rock quarry which was operated periodically over the past few decades to support provincial transportation and infrastructure projects. Other land uses in the vicinity of the Project include a variety of business and industrial operations north and east of the site in the Aerotech Industrial Park such as Maritime Fence, Irving Oil CNG, Clean Earth Technologies Inc., and L3 Electronics Systems as well as the Halifax Stanfield International Airport. Located west of the proposed quarry is the north bound Highway 102 weigh station, operated by the Department of Transportation and Infrastructure Renewal (NSTIR). Further west, across Highway 102, are a number of residential subdivisions in Fall River. Approximately 1.5 km south west of the Project is a residential community known as the Miller Lake West subdivision.

Immediately south of the site is Perrin Drive which runs northeast – southwest. The majority of Perrin Drive, between the entrance to the quarry and Miller Lake West subdivision, is impassable via automobile. The Maritimes and Northeast Pipeline Halifax Lateral runs parallel to Perrin Drive, on the south side. Scotian owns the land parcels on both sides of Perrin Drive which are also undeveloped. The Waverley Game Sanctuary and the Waverley Salmon River Long Lake Wilderness Area are located south and east of the Project.

Scotian commissioned a number of field surveys across the properties purchased in the vicinity of the proposed Project to support plans for various types of potential developments (e.g., commercial, residential, industrial). Surveys were conducted for wetlands and vegetation communities, surface water and fish / fish habitat, and wildlife. The boundary of the proposed Project footprint was selected to avoid wetlands and watercourses and optimize the resource available and access to it. As specified in the Pit and Quarry Guidelines (NSEL 1999), a 30 metre buffer will be maintained between the quarry footprint and all watercourses and wetlands. The quarry will make use of existing, well-established access roads within the property.

Project Components

The proposed quarry operation will consist of the quarry floor and working face, a laydown area for the crushing equipment, overburden and aggregate stockpiles, a wash plant, weight scales, and a sedimentation pond. Topsoil, grubbing material and overburden that will be stripped prior to drilling and blasting will be stored on-site for subsequent use during progressive site reclamation. These materials will be stabilized with hydroseed or other suitable material (e.g., straw mulch) to reduce the potential for erosion and sedimentation.

The crushing equipment to be used at the quarry is portable; however, it may be set up on the quarry floor as a permanent / stationary installation, optimally positioned for long-term use (i.e., the life of the quarry). Aggregate stockpiles will be located as space allows within the quarry footprint. As the quarry expands and additional space is created, a dedicated stockpile area will be created.

Crushing equipment, or crushing spread, will consist of a series of crushers, screens, conveyors, hoppers and surge piles designed to breakdown the material efficiently to smaller size fractions. The design of the crushing and screening circuit is a function of the rock type and target product mix required to produce construction grade material for modern practices. Given the variation in types of aggregates to be produced, the configuration of the crushing spread is subject to change. Surface runoff and quarry drainage will be collected on the quarry floor and will drain to a settling pond to be constructed in at the lowest point (i.e., southern end).

Access to the Project site is from the north via Highway 102 Exit 5A to Aerotech Drive then south to an existing private road off of Perrin Drive.

The proposed quarry operation will consist of the quarry floor and working face, a laydown area for the crushing equipment, overburden and aggregate stockpiles, a wash plant, weight scales, and a sedimentation pond. Topsoil, grubbing material and overburden that will be stripped prior to drilling and blasting will be stored on-site for subsequent use during progressive site reclamation. These materials will be stabilized with hydroseed or other suitable material (e.g., straw mulch) to reduce the potential for erosion and sedimentation.

The crushing equipment to be used at the quarry is portable; however, it may be set up on the quarry floor as a permanent / stationary installation, optimally positioned for long-term use (i.e., the life of the quarry). Aggregate stockpiles will be located as space allows within the quarry footprint. As the quarry expands and additional space is created, a dedicated stockpile area will be created.

Crushing equipment, or crushing spread, will consist of a series of crushers, screens, conveyors, hoppers and surge piles designed to breakdown the material efficiently to smaller size fractions. The design of the crushing and screening circuit is a function of the rock type and target product mix required to produce construction grade material for modern practices. Given the variation in types of aggregates to be produced, the configuration of the crushing spread is subject to change. Surface runoff and quarry drainage will be collected on the quarry floor and will drain to a settling pond to be constructed in at the lowest point (i.e., southern end).

Access to the Project site is from the north via Highway 102 Exit 5A to Aerotech Drive then south to an existing private road off of Perrin Drive.

Site Preparation and Construction

Site preparation and construction typically will begin with clearing trees, grubbing (i.e., removal of stumps), stripping of topsoil, and removal of overburden, however the site has been cleared, grubbed and stripped based on a previously issued approval from NSE. Stockpiles will be stabilized with hydroseed and/or straw mulch to minimize erosion and sedimentation for subsequent use during site reclamation.

To the extent possible, surface flow will be directed around the site and/or away from disturbed areas. Quarry drainage and surface runoff collection and controls will be in place for the quarry at the commencement of construction. The settling pond will be designed to hold a sufficient volume of water to allow for settling of suspended sediment. Overflow from the pond, if any, will be directed to a vegetated area (on lands owned by Scotian Materials) for further filtration. Any water discharged will be monitored and reported in compliance with NSE regulations.

Site preparation and construction work will continue once all required permits are obtained.

Site preparation and construction typically will begin with clearing trees, grubbing (i.e., removal of stumps), stripping of topsoil, and removal of overburden, however the site has been cleared, grubbed and stripped based on a previously issued approval from NSE. Stockpiles will be stabilized with hydroseed and/or straw mulch to minimize erosion and sedimentation for subsequent use during site reclamation.

To the extent possible, surface flow will be directed around the site and/or away from disturbed areas. Quarry drainage and surface runoff collection and controls will be in place for the quarry at the commencement of construction. The settling pond will be designed to hold a sufficient volume of water to allow for settling of suspended sediment. Overflow from the pond, if any, will be directed to a vegetated area (on lands owned by Scotian Materials) for further filtration. Any water discharged will be monitored and reported in compliance with NSE regulations.

Site preparation and construction work will continue once all required permits are obtained.

Quarry Operations

The proposed Project activities will be consistent with industry standard practice and will be in accordance with the NSE Pit and Quarry Guidelines (NSEL 1999). These guidelines apply to all pit and quarry operations in the province of Nova Scotia and provide: separation distances for operations, including blasting; liquid effluent discharge level limits; suspended particulate matter limits; sound level limits; and requirements for a reclamation plan and security bond.

Aggregate production will begin with drilling and blasting. Drilling and blasting will be conducted by an independent licensed contractor who will be responsible for blast designs and methods in accordance with the General Blasting Regulations pursuant to the Nova Scotia Occupational Health and Safety Act (1996). Further, all blasting activity will be conducted in accordance with the Pit and Quarry Guidelines (NSEL 1999).

It is anticipated that blasting could occur up to 4 times a year based on the proposed production rate of 200,000 tonnes per year.

The frequency of blasting is based on the aggregate supply contracts awarded; (i.e., supply and demand). Similarly, the number of loaded trucks hauling material from the site is also based on aggregate supply contracts.

The current site topography within the proposed quarry area varies from approximately 110 metres above sea level (masl) in the northern end to approximately 96 masl in the southern end. The quarry will be excavated to an ultimate elevation of 88 masl. It is expected that quarry excavation will not take place below the groundwater table. Should site conditions indicate that the proposed bottom of the quarry extends below the water table, a hydrogeological study shall be carried out, as per the Pit and Quarry Guidelines (NSEL 1999).

Blasted rock will be transferred from the working face to the crushing spread. The blasted rock will be loaded into the jaw crusher (primary crusher) that breaks the rock down into approximately 305 mm (12 inch) minus material. From there, the material will be conveyed into another feeder bin and screened. From the screen, material will be conveyed to two separate cone crushers, depending on size. Beyond the primary crushing and screening phase, additional crushing and screening will depend on the size of the aggregate required to supply specifications of the contracts. The material will be re-circulated to the screen and will be crushed again until the required aggregate size is attained at which time the aggregate will be conveyed into various stockpiles. A video of our typical crushing process can be seen here.

The various aggregate products will be stockpiled at the site until they are transported to local markets via tandem trucks or tractor trailer trucks. All quarry related truck traffic will access the site from the north via Aerotech Drive and Highway 102 exit 5A. Quarry truck traffic will not travel south along Perrin Drive.

The operating schedule for the quarry will generally be five days a week, ten to twelve hours a day and eight to ten months a year, weather permitting. This schedule may be modified in the event a significant aggregate supply contract is awarded and, as such, Scotian requests that they maintain the flexibility to increase the production rate and operating schedule to accommodate a larger contract. This operation schedule may be reduced or extended depending on the aggregate supply contracts awarded.

Scotian has commissioned resource assessment studies and is confident that there is sufficient resource present within the proposed quarry boundary to allow for an operation of 5-10 years, depending on the actual annual rate.

The proposed Project is expected to employ at least 10 to 12 direct employees throughout the year, with five to six additional secondary workers being employed by the blasting contractor for at least one week, every four to six weeks. Additional secondary employment through hauling / trucking contractors is estimated to result in the employment of another 20 to 30 workers.

The proposed Project activities will be consistent with industry standard practice and will be in accordance with the NSE Pit and Quarry Guidelines (NSEL 1999). These guidelines apply to all pit and quarry operations in the province of Nova Scotia and provide: separation distances for operations, including blasting; liquid effluent discharge level limits; suspended particulate matter limits; sound level limits; and requirements for a reclamation plan and security bond.

Aggregate production will begin with drilling and blasting. Drilling and blasting will be conducted by an independent licensed contractor who will be responsible for blast designs and methods in accordance with the General Blasting Regulations pursuant to the Nova Scotia Occupational Health and Safety Act (1996). Further, all blasting activity will be conducted in accordance with the Pit and Quarry Guidelines (NSEL 1999).

It is anticipated that blasting could occur up to 4 times a year based on the proposed production rate of 200,000 tonnes per year.

The frequency of blasting is based on the aggregate supply contracts awarded; (i.e., supply and demand). Similarly, the number of loaded trucks hauling material from the site is also based on aggregate supply contracts.

The current site topography within the proposed quarry area varies from approximately 110 metres above sea level (masl) in the northern end to approximately 96 masl in the southern end. The quarry will be excavated to an ultimate elevation of 88 masl. It is expected that quarry excavation will not take place below the groundwater table. Should site conditions indicate that the proposed bottom of the quarry extends below the water table, a hydrogeological study shall be carried out, as per the Pit and Quarry Guidelines (NSEL 1999).

Blasted rock will be transferred from the working face to the crushing spread. The blasted rock will be loaded into the jaw crusher (primary crusher) that breaks the rock down into approximately 305 mm (12 inch) minus material. From there, the material will be conveyed into another feeder bin and screened. From the screen, material will be conveyed to two separate cone crushers, depending on size. Beyond the primary crushing and screening phase, additional crushing and screening will depend on the size of the aggregate required to supply specifications of the contracts. The material will be re-circulated to the screen and will be crushed again until the required aggregate size is attained at which time the aggregate will be conveyed into various stockpiles. A video of our typical crushing process can be seen here.

The various aggregate products will be stockpiled at the site until they are transported to local markets via tandem trucks or tractor trailer trucks. All quarry related truck traffic will access the site from the north via Aerotech Drive and Highway 102 exit 5A. Quarry truck traffic will not travel south along Perrin Drive.

The operating schedule for the quarry will generally be five days a week, ten to twelve hours a day and eight to ten months a year, weather permitting. This schedule may be modified in the event a significant aggregate supply contract is awarded and, as such, Scotian requests that they maintain the flexibility to increase the production rate and operating schedule to accommodate a larger contract. This operation schedule may be reduced or extended depending on the aggregate supply contracts awarded.

Scotian has commissioned resource assessment studies and is confident that there is sufficient resource present within the proposed quarry boundary to allow for an operation of 5-10 years, depending on the actual annual rate.

The proposed Project is expected to employ at least 10 to 12 direct employees throughout the year, with five to six additional secondary workers being employed by the blasting contractor for at least one week, every four to six weeks. Additional secondary employment through hauling / trucking contractors is estimated to result in the employment of another 20 to 30 workers.

Preliminary Rehabilitation Plans

Scotian Materials has commissioned a Master Development Plan for their lands in the area of the Project and the proposed end use of the quarry land is commercial / industrial.

The quarry will be developed in consideration of the end land use; that is, it will be excavated to a depth to allow for efficient commercial development. Progressive and final reclamation activities will be done in consideration of the end use of the land. Reclamation activities will be limited to grading and contouring of the lands and establishing appropriate drainage to support future development as well as stabilizing the site from any safety hazards and erosion. Exposed erodible materials will be stabilized with rock or hydroseed upon final grading. Site re-vegetation and stabilization will occur during the appropriate seasons to promote and aid in their success.

As required, a final rehabilitation plan will be submitted to NSE that will include the details of surface contouring (e.g., 3:1 slopes), establishing site drainage, revegetation and site stabilization. The plan will also include the estimated cost for labour, equipment and supplies to undertake the rehabilitation work. The plan will also give consideration to reclaiming the former quarry operated by other contractors for Nova Scotia Department of Transportation and Infrastructure projects that is located 235 m from the Project.

If approval is received, Scotian will provide the required security for the quarry as required by NSE. Final security shall be posted once the final rehabilitation plan has been reviewed and accepted by NSE.

Scotian Materials has commissioned a Master Development Plan for their lands in the area of the Project and the proposed end use of the quarry land is commercial / industrial.

The quarry will be developed in consideration of the end land use; that is, it will be excavated to a depth to allow for efficient commercial development. Progressive and final reclamation activities will be done in consideration of the end use of the land. Reclamation activities will be limited to grading and contouring of the lands and establishing appropriate drainage to support future development as well as stabilizing the site from any safety hazards and erosion. Exposed erodible materials will be stabilized with rock or hydroseed upon final grading. Site re-vegetation and stabilization will occur during the appropriate seasons to promote and aid in their success.

As required, a final rehabilitation plan will be submitted to NSE that will include the details of surface contouring (e.g., 3:1 slopes), establishing site drainage, revegetation and site stabilization. The plan will also include the estimated cost for labour, equipment and supplies to undertake the rehabilitation work. The plan will also give consideration to reclaiming the former quarry operated by other contractors for Nova Scotia Department of Transportation and Infrastructure projects that is located 235 m from the Project.

If approval is received, Scotian will provide the required security for the quarry as required by NSE. Final security shall be posted once the final rehabilitation plan has been reviewed and accepted by NSE.

Wastes and Emissions

Other than the scale house and/or portable office trailer and portable sanitary station, there will be no permanent buildings located on the site. As such, there will be minimal waste generated. The implementation and use of standard environmental controls such as proper treatment, handling, storage, and disposal as well as compliance with regulations will minimize any potential environmental damage to the area from Project-related waste, emissions, and discharges.

Other than the scale house and/or portable office trailer and portable sanitary station, there will be no permanent buildings located on the site. As such, there will be minimal waste generated. The implementation and use of standard environmental controls such as proper treatment, handling, storage, and disposal as well as compliance with regulations will minimize any potential environmental damage to the area from Project-related waste, emissions, and discharges.

Surface Runoff

Although there are not surface waterbodies within 30 m of the proposed footprint, the Project has the potential to affect surface water quality down gradient of the development. To avoid or minimize water quality effects, surface water will be diverted around the site to minimize the volume of water that may require treatment for suspended sediments. Onsite, erosion controls will be in place to ensure that site runoff generated during operations is managed appropriately. Surface runoff will collect on the quarry floor and drainage ditches, as required, and will be directed to a settling pond to be constructed in the southern end of the site where it will evaporate or infiltrate into the ground. Also, water from the settling pond will be used for washing aggregates as required. The settling pond will expand as the quarry operation progresses to ensure there is sufficient capacity to treat the anticipated volume of runoff. Overflow, if any, will be through an overflow weir and will be directed as sheet flow to a vegetated area for additional filtration. Surface runoff will be monitored and sampled at the request of NSE and in accordance with the Pit and Quarry Guidelines (NSEL 1999) and/or the terms and conditions of the Industrial Approval (once obtained) to ensure total suspended solids levels do not exceed effluent discharge limits indicated in the Pit and Quarry Guidelines (NSEL 1999) prior to entering a watercourse or beyond the property boundaries:

Although there are not surface waterbodies within 30 m of the proposed footprint, the Project has the potential to affect surface water quality down gradient of the development. To avoid or minimize water quality effects, surface water will be diverted around the site to minimize the volume of water that may require treatment for suspended sediments. Onsite, erosion controls will be in place to ensure that site runoff generated during operations is managed appropriately. Surface runoff will collect on the quarry floor and drainage ditches, as required, and will be directed to a settling pond to be constructed in the southern end of the site where it will evaporate or infiltrate into the ground. Also, water from the settling pond will be used for washing aggregates as required. The settling pond will expand as the quarry operation progresses to ensure there is sufficient capacity to treat the anticipated volume of runoff. Overflow, if any, will be through an overflow weir and will be directed as sheet flow to a vegetated area for additional filtration. Surface runoff will be monitored and sampled at the request of NSE and in accordance with the Pit and Quarry Guidelines (NSEL 1999) and/or the terms and conditions of the Industrial Approval (once obtained) to ensure total suspended solids levels do not exceed effluent discharge limits indicated in the Pit and Quarry Guidelines (NSEL 1999) prior to entering a watercourse or beyond the property boundaries:

- maximum suspended solids concentration in any grab sample - 50 mg/l; and,

- maximum arithmetic monthly average suspended solids concentration – 25 mg/l.

Groundwater

In general, blasting has the potential to affect groundwater quality and quantity. In consideration of this, the use of groundwater as potable water supply by residents down gradient of the Project, and the concerns raised by the public, we offer the following discussion.

The understanding of the water table, groundwater quantity and groundwater quality have been inferred based upon the Nova Scotia Water Well Database and publically available mapping and studies in the area.

Based upon topographic mapping obtained from Natural Resources Canada (2015) the shallow groundwater flow is inferred to follow topography and flow towards the southeast. The regional groundwater flow is inferred to flow towards the south towards Miller Lake and then eventually discharge to the southwest towards the Halifax Harbour.

The groundwater resources in the area were previously studied by T. Lay and Nolan, White & Associates (1979). This study reports that groundwater from the Goldenville Formation is generally considered good drinking water quality but, may contain elevated concentrations of iron, manganese and arsenic and may have low pH.

Therefore, it is assumed that the water quality of the domestic wells at Miller Lake West is generally of acceptable quality and meets the Nova Scotia Department of Environment potable water standards as well as the Canadian Drinking Water Quality Guidelines with potential treatment requirements for hardness, iron, manganese and arsenic.

Yield from bedrock wells in the Meguma Supergroup are typically only four to 38 litres per minute (lpm) or 1 – 10 gallons per minute (gpm) with up to 190 lpm (50 gpm) in some cases. Hydraulic conductivity is typically fracture controlled (DMPNS 1967).

To understand the number and type of groundwater users in the area, the Nova Scotia Water Well Database was searched for wells located in the closest subdivision, Miller Lake West, which is located approximately 1.5 km to the southwest of the Project. The properties on Delray Court, Perrin Drive, Mornington Court, Oakbank Lane and Preakness Crescent were selected as these are the closest streets to the quarry.

Water well records typically report yields of less than 5 lpm with one reporting yields greater than 100 lpm. In general, domestic wells with a yield of 9 lpm (2 gpm) are considered to have adequate yield (Lay et al. 1979). Therefore, the well yields in the area of Miller Lake West are lower than generally desired. The wide range of well yields can be attributed to the fracture controlled hydraulic conductivity of the bedrock aquifer and the abundance of low reported yields is likely to be a reflection of the typical well construction and testing being carried out for single household domestic water supplies.

The well log database indicates that most domestic water wells are obtaining water from the quartzite or shale bedrock which is presumed to be bedrock of the Goldenville Formation based on the bedrock mapping (Home et al. 2009). The Goldenville Formation extends from the proposed quarry footprint to the Miller Lake West housing subdivision and beyond. The groundwater wells used for domestic supply in the Miller Lake West subdivision are inferred to be located down gradient of the quarry based on topography. The closest domestic well is located on Perrin Drive and is located approximately 1.5 km from the proposed Project footprint. In relative terms in Nova Scotia, this is a considerable distance from the proposed quarry.

It is noted that there are local occurrences of sulphide-bearing minerals (e.g. pyrite) in the Goldenville Formation which has potential for acid-rock drainage. In the Halifax area, acid rock drainage is typically associated with slate which can be found within the Goldenville Formation; however, in the area of the Project, this formation it is appears to be predominantly quartzite. Scotian obtained samples for analysis of acid producing potential.

The results indicate that the rock is well below the threshold for acid producing potential (i.e., 0.92 kg H2SO4/tonne vs the threshold of 12.51 kg H2SO4/tonne). The bedrock at the quarry will be inspected for sulphide mineralization regularly to determine if sulphide-bearing slate is present within the quartzite resource. If found, it is recommended that acid base accounting be analysed to determine if the non-sulphide bearing rock contains sufficient carbonate minerals to neutralize any acid drainage that may result from the sulphide-bearing minerals.

The potential effects of quarry activities on groundwater quantity or quality at this distance are considered to be low. In the unlikely event that quarrying activities cause water quality effects of domestic water supplies, Scotian will repair or replace the domestic supply adversely affected to meet the Nova Scotia Department of Environment Environmental Quality Standards for potable water and the Canadian Drinking Water Guidelines, which may include treatment for common naturally occurring water quality issues as hardness, iron, manganese and arsenic.

In general, blasting has the potential to affect groundwater quality and quantity. In consideration of this, the use of groundwater as potable water supply by residents down gradient of the Project, and the concerns raised by the public, we offer the following discussion.

The understanding of the water table, groundwater quantity and groundwater quality have been inferred based upon the Nova Scotia Water Well Database and publically available mapping and studies in the area.

Based upon topographic mapping obtained from Natural Resources Canada (2015) the shallow groundwater flow is inferred to follow topography and flow towards the southeast. The regional groundwater flow is inferred to flow towards the south towards Miller Lake and then eventually discharge to the southwest towards the Halifax Harbour.

The groundwater resources in the area were previously studied by T. Lay and Nolan, White & Associates (1979). This study reports that groundwater from the Goldenville Formation is generally considered good drinking water quality but, may contain elevated concentrations of iron, manganese and arsenic and may have low pH.

Therefore, it is assumed that the water quality of the domestic wells at Miller Lake West is generally of acceptable quality and meets the Nova Scotia Department of Environment potable water standards as well as the Canadian Drinking Water Quality Guidelines with potential treatment requirements for hardness, iron, manganese and arsenic.

Yield from bedrock wells in the Meguma Supergroup are typically only four to 38 litres per minute (lpm) or 1 – 10 gallons per minute (gpm) with up to 190 lpm (50 gpm) in some cases. Hydraulic conductivity is typically fracture controlled (DMPNS 1967).

To understand the number and type of groundwater users in the area, the Nova Scotia Water Well Database was searched for wells located in the closest subdivision, Miller Lake West, which is located approximately 1.5 km to the southwest of the Project. The properties on Delray Court, Perrin Drive, Mornington Court, Oakbank Lane and Preakness Crescent were selected as these are the closest streets to the quarry.

Water well records typically report yields of less than 5 lpm with one reporting yields greater than 100 lpm. In general, domestic wells with a yield of 9 lpm (2 gpm) are considered to have adequate yield (Lay et al. 1979). Therefore, the well yields in the area of Miller Lake West are lower than generally desired. The wide range of well yields can be attributed to the fracture controlled hydraulic conductivity of the bedrock aquifer and the abundance of low reported yields is likely to be a reflection of the typical well construction and testing being carried out for single household domestic water supplies.

The well log database indicates that most domestic water wells are obtaining water from the quartzite or shale bedrock which is presumed to be bedrock of the Goldenville Formation based on the bedrock mapping (Home et al. 2009). The Goldenville Formation extends from the proposed quarry footprint to the Miller Lake West housing subdivision and beyond. The groundwater wells used for domestic supply in the Miller Lake West subdivision are inferred to be located down gradient of the quarry based on topography. The closest domestic well is located on Perrin Drive and is located approximately 1.5 km from the proposed Project footprint. In relative terms in Nova Scotia, this is a considerable distance from the proposed quarry.

It is noted that there are local occurrences of sulphide-bearing minerals (e.g. pyrite) in the Goldenville Formation which has potential for acid-rock drainage. In the Halifax area, acid rock drainage is typically associated with slate which can be found within the Goldenville Formation; however, in the area of the Project, this formation it is appears to be predominantly quartzite. Scotian obtained samples for analysis of acid producing potential.

The results indicate that the rock is well below the threshold for acid producing potential (i.e., 0.92 kg H2SO4/tonne vs the threshold of 12.51 kg H2SO4/tonne). The bedrock at the quarry will be inspected for sulphide mineralization regularly to determine if sulphide-bearing slate is present within the quartzite resource. If found, it is recommended that acid base accounting be analysed to determine if the non-sulphide bearing rock contains sufficient carbonate minerals to neutralize any acid drainage that may result from the sulphide-bearing minerals.

The potential effects of quarry activities on groundwater quantity or quality at this distance are considered to be low. In the unlikely event that quarrying activities cause water quality effects of domestic water supplies, Scotian will repair or replace the domestic supply adversely affected to meet the Nova Scotia Department of Environment Environmental Quality Standards for potable water and the Canadian Drinking Water Guidelines, which may include treatment for common naturally occurring water quality issues as hardness, iron, manganese and arsenic.

Air Quality

The proposed quarry will result in air emissions related to exhaust from vehicle and equipment operation and fugitive dust related to drilling and blasting, truck and vehicle traffic/movement, crushing and screening, material handling and transport, and wind erosion across the site. Air quality concerns related to dust have been raised by the public during consultation.

Total suspended particulate (TSP), PM10 and PM2.5 (particulate matter less than 10 micrometres and 2.5 micrometres, respectively) have the greatest potential to be transported downwind because of their small size. The quantity of particulate emissions released also decreases with smaller particle size. Once transported away from the immediate source area, a portion of the particulate matter will deposit out of the air flow on to the ground. Large particles (<100 μm) will fallout sooner, generally within a few meters, and at a greater rate than the smaller sizes. Particles that are 30 to 100 μm in diameter are likely to settle within approximately 100 m or less from the source. The smaller particles will fallout at a slower rate and travel a longer distance and will also be dispersed over a broader area moreso than the larger sized particles. Given the distance between the source and the nearest sensitive receptors (i.e., approximately 1,500 m to the southwest) coupled with the prevailing wind direction (i.e., to the northeast, away from the nearest sensitive receptors), levels of PM at 1.5 km should be minor for a well maintained quarry operation which is following Best Management Practices (BMPs) described below.

Dust emissions will be controlled with the application of water, obtained from the water that is pooled on the quarry floor or the settling pond. To minimize the generation of dust, the working areas and laydown areas will be covered with blasted rock and stockpiles of erodible material (i.e., overburden and topsoil) will be stabilized with mulch and/or hydroseed. Dust generated by truck movement along the access road will be minimized by speed control, proper truck loading, application of dust suppressants, proper construction of on-site roads, and/ or other means as per the terms and conditions of the Industrial Approval (once obtained).

Exhausts emissions from equipment and vehicles will be mitigated by ensuring vehicles are maintained in good working order to ensure efficient operation and minimization of emissions. Consideration will be given to methods to reduce idling, as feasible.

Monitoring of airborne particulate emissions (dust) will be conducted at the request of NSE, in accordance with the Pit and Quarry Guidelines (NSEL 1999), the Nova Scotia Air Quality Regulations and the Industrial Approval, to be issued by NSE for the Project, and shall not exceed the following limits at the property boundaries:

The proposed quarry will result in air emissions related to exhaust from vehicle and equipment operation and fugitive dust related to drilling and blasting, truck and vehicle traffic/movement, crushing and screening, material handling and transport, and wind erosion across the site. Air quality concerns related to dust have been raised by the public during consultation.

Total suspended particulate (TSP), PM10 and PM2.5 (particulate matter less than 10 micrometres and 2.5 micrometres, respectively) have the greatest potential to be transported downwind because of their small size. The quantity of particulate emissions released also decreases with smaller particle size. Once transported away from the immediate source area, a portion of the particulate matter will deposit out of the air flow on to the ground. Large particles (<100 μm) will fallout sooner, generally within a few meters, and at a greater rate than the smaller sizes. Particles that are 30 to 100 μm in diameter are likely to settle within approximately 100 m or less from the source. The smaller particles will fallout at a slower rate and travel a longer distance and will also be dispersed over a broader area moreso than the larger sized particles. Given the distance between the source and the nearest sensitive receptors (i.e., approximately 1,500 m to the southwest) coupled with the prevailing wind direction (i.e., to the northeast, away from the nearest sensitive receptors), levels of PM at 1.5 km should be minor for a well maintained quarry operation which is following Best Management Practices (BMPs) described below.

Dust emissions will be controlled with the application of water, obtained from the water that is pooled on the quarry floor or the settling pond. To minimize the generation of dust, the working areas and laydown areas will be covered with blasted rock and stockpiles of erodible material (i.e., overburden and topsoil) will be stabilized with mulch and/or hydroseed. Dust generated by truck movement along the access road will be minimized by speed control, proper truck loading, application of dust suppressants, proper construction of on-site roads, and/ or other means as per the terms and conditions of the Industrial Approval (once obtained).

Exhausts emissions from equipment and vehicles will be mitigated by ensuring vehicles are maintained in good working order to ensure efficient operation and minimization of emissions. Consideration will be given to methods to reduce idling, as feasible.

Monitoring of airborne particulate emissions (dust) will be conducted at the request of NSE, in accordance with the Pit and Quarry Guidelines (NSEL 1999), the Nova Scotia Air Quality Regulations and the Industrial Approval, to be issued by NSE for the Project, and shall not exceed the following limits at the property boundaries:

- annual Geometric Mean 70 μg/m3; and,

- daily Average (24 hrs) 120 μg/m3.

Noise

Noise (i.e., unwanted sound) is a potential Project-related effect and has been raised as an issue of concern by the public during consultation. As such, a noise monitoring program was conducted between August 4th and August 11th, 2012 to establish existing sound levels (i.e., ambient noise) at three locations, including within the proposed Project site (Figure 6). Table 2 details the monitoring locations.

Noise (i.e., unwanted sound) is a potential Project-related effect and has been raised as an issue of concern by the public during consultation. As such, a noise monitoring program was conducted between August 4th and August 11th, 2012 to establish existing sound levels (i.e., ambient noise) at three locations, including within the proposed Project site (Figure 6). Table 2 details the monitoring locations.

Larson Davis 720 sound level meters were used to collect the sound level data and establish the ambient conditions. The daytime, evening and night-time period average background sound levels during the monitoring period were calculated. Monitoring data captured during inclement weather was removed from the dataset.

At the time of the survey, it was confirmed (using hand held instruments) that sound levels at the monitoring locations were generally associated with Highway 102 traffic. Although LD720#2 was located further from Highway 102 than LD720#1, the sound levels at LD720#2 were generally higher than those monitored at LD720#1. These higher sound levels were attributed to the fact that the LD720#2 monitoring location was located near an open field, with few trees.

Monitoring data generally shows that the ambient sound levels at the areas monitored are higher than the sound levels expected in a rural environment. This is attributed to the proximity to Highway 102 traffic and intermittent airport traffic.

Noise modelling was conducted in accordance with an internationally accepted standard for the prediction of noise outdoors (ISO 9613). To be conservative, attenuation from barriers (e.g., pit walls), ground effects (e.g., topography and vegetation), and air adsorption were not included in the modelling exercise. Also, preliminary noise predictions have been made assuming a downwind or moderate temperature inversion conditions, resulting in elevated predicted levels which is another conservative approach.

Monitoring data generally shows that the ambient sound levels at the areas monitored are higher than the sound levels expected in a rural environment. This is attributed to the proximity to Highway 102 traffic and intermittent airport traffic.

Noise modelling was conducted in accordance with an internationally accepted standard for the prediction of noise outdoors (ISO 9613). To be conservative, attenuation from barriers (e.g., pit walls), ground effects (e.g., topography and vegetation), and air adsorption were not included in the modelling exercise. Also, preliminary noise predictions have been made assuming a downwind or moderate temperature inversion conditions, resulting in elevated predicted levels which is another conservative approach.

Based on the conservative noise modelling, it is expected the noise levels from the proposed Project, would be at or below 40 dBA within 1,500 m of the site operations and well within the limits indicated in the Pit and Quarry Guidelines (NSEL 1999). This noise level is similar to that of a quiet living room and would be well below the baseline noise levels measured in August 2012.

To further minimize noise, the following mitigation will be implemented:

To further minimize noise, the following mitigation will be implemented:

- limit activities and vehicle traffic to daytime hours, to the extent possible;

- consider evaluating the use of newer technologies associated with back-up alarms to reduce to amount of noise from equipment operation;

- maintain vehicles and equipment regularly and adequately; and,

- perform blasting during day time only and, to the extent possible, at a regular scheduled time.

Solid and Hazardous Waste

Waste management options will be considered to minimize the waste generated by Project activities and to reuse and/or recycle wastes when feasible. All solid waste will be properly collected and stored until such time that it can be transported to a provincially approved waste disposal facility.

The only hazardous materials anticipated onsite will be those associated with the normal operation and maintenance of construction equipment. These substances include gasoline, diesel fuel, lubricants and antifreeze liquid. No onsite storage of such materials is anticipated, since all refueling and maintenance will be carried out on an as needed basis by a mobile fleet in a designated area within the quarry by licenced contractors. The fueling and vehicle maintenance area will consist of a clay-lined containment area enclosed within side curbs and a sloping floor. This will contain any spills or leaks during fueling and/or vehicle maintenance.

The following mitigation strategies will be implemented to avoid or minimize potential environmental effects from hazardous materials:

Waste management options will be considered to minimize the waste generated by Project activities and to reuse and/or recycle wastes when feasible. All solid waste will be properly collected and stored until such time that it can be transported to a provincially approved waste disposal facility.

The only hazardous materials anticipated onsite will be those associated with the normal operation and maintenance of construction equipment. These substances include gasoline, diesel fuel, lubricants and antifreeze liquid. No onsite storage of such materials is anticipated, since all refueling and maintenance will be carried out on an as needed basis by a mobile fleet in a designated area within the quarry by licenced contractors. The fueling and vehicle maintenance area will consist of a clay-lined containment area enclosed within side curbs and a sloping floor. This will contain any spills or leaks during fueling and/or vehicle maintenance.

The following mitigation strategies will be implemented to avoid or minimize potential environmental effects from hazardous materials:

- Repairs and refuelling of equipment will not occur within 30 m of a watercourse or wetland.

- Used oil and filters will be removed from the site for proper disposal and recycling.

- All refuelling activities will comply with the NS Petroleum Management Regulations (NS Reg. 44/202). Unforeseen events such as leaks or spills will be responded to immediately.

- Equipment operators will remain with the equipment at all times during refueling in accordance with the Petroleum Management Regulations of the Nova Scotia Environment Act.

- Spills will be reported to NSE in accordance with the Emergency Spill Regulations (NS Reg. 59/95).

- Contaminated materials will be stored in an appropriate manner in a designated location until such time as it can be transported offsite for treatment and/or disposal at an approved facility.